When you have a commercial refrigeration unit installed, you typically focus on things like the interior capacity, overall size to ensure it fits in your store, restaurant, or supermarket, as well as the efficiency of the unit and how much it costs to operate. However, one thing that you really need to consider is how to keep your unit safely operating.

When you have a commercial refrigeration unit installed, you typically focus on things like the interior capacity, overall size to ensure it fits in your store, restaurant, or supermarket, as well as the efficiency of the unit and how much it costs to operate. However, one thing that you really need to consider is how to keep your unit safely operating.

There are a few safety guidelines that should be followed when you have any type of commercial refrigerator installed in your business. Not only does following these guidelines increase the longevity and optimize performance, but it also keeps your business safe from potential damage that could be caused by a faulty installation or poor maintenance.

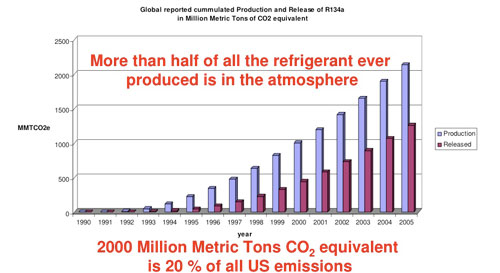

Refrigerant within the system is required in order to be able to reach lower temperatures needed to preserve food and prevent it from spoiling. If your refrigerant is low, this indicates that there is a leak somewhere within your system. Instead of simply refilling the system, the leak must be detected and repaired. Failure to do so results in the refrigerant being released into the atmosphere, which is a violation of the Clean Air Act’s regulations and can result in heavy fines.

Another important guideline to note is that you should always make sure that fans are unobstructed. Since these fans work to push out hot air to keep the interior of a cooler cold, blocking them can not only run up your utility bill, but it can be dangerous for the components in your unit. Your unit should never be pulled out from the wall a bit, particularly where there are fans or vents to prevent overheating. Read more in our previous post on maintaining proper commercial refrigerator temperatures.

The thermometer and all parts should be kept in working order to maintain the proper temperatures. Temperatures that are too low can result in food that is frozen and spoiled, while higher temperatures can help bacteria breed and spoil everything contained within your unit.

If a leak is detected in your drain line or around any other part in your unit, you should have it immediately inspected and repaired, as this can result in standing water that can lead to slips and falls by your employees or customers.

Regular maintenance is a must to ensure complete safety of your product. Faulty wiring can result in failure at best, or at worst, a fire that can damage your property. All electrical components should be checked at least semi-annually or quarterly. Other important components including the condenser coils, evaporator coils, and drain lines. If any of these components fail, your refrigerator will not maintain its temperature, your energy bills may rise significantly, and you put your whole unit at risk for damage.

Several times a year, a licensed commercial refrigeration professional should fully inspect your unit and should make repairs as needed. While you can certainly take a look at certain components yourself, the more extensive maintenance and repairs should out be performed by a licensed and experienced professional.

old commercial refrigeration equipment, inefficient HVAC equipment, leaks in the system, over-sized compressors, out of date refrigerants, and commercial refrigeration units that were not designed correctly from the start. All of these issues can have drastic impact on a company’s bottom line due to the ever increasing cost of energy.

old commercial refrigeration equipment, inefficient HVAC equipment, leaks in the system, over-sized compressors, out of date refrigerants, and commercial refrigeration units that were not designed correctly from the start. All of these issues can have drastic impact on a company’s bottom line due to the ever increasing cost of energy. Natural refrigerants are non-synthetic substances which can be used as cooling agents in commercial refrigeration equipment and air conditioners. These include naturally occurring substances like water, air, CO2, ammonia, and hydrocarbons like propane, butane, and cyclopentane. While they have been used for years as refrigerants they are only just now beginning to replace synthetic refrigerants in commercial refrigeration equipment.

Natural refrigerants are non-synthetic substances which can be used as cooling agents in commercial refrigeration equipment and air conditioners. These include naturally occurring substances like water, air, CO2, ammonia, and hydrocarbons like propane, butane, and cyclopentane. While they have been used for years as refrigerants they are only just now beginning to replace synthetic refrigerants in commercial refrigeration equipment. S Alternative Fluorocarbons Acceptability Study, 2007). To reduce the Global Warming Potential and provide zero ozone depleting potential as required by the Montreal and Kyoto Protocols, commercial refrigeration equipment will eventually have to be cooled by natural refrigerants. It is estimated that if commercial refrigeration equipment in the United States alone was converted to natural refrigerants, the industry would be able to reduce emission of CO2 and other greenhouse gases by 22 million metric tons annually.

S Alternative Fluorocarbons Acceptability Study, 2007). To reduce the Global Warming Potential and provide zero ozone depleting potential as required by the Montreal and Kyoto Protocols, commercial refrigeration equipment will eventually have to be cooled by natural refrigerants. It is estimated that if commercial refrigeration equipment in the United States alone was converted to natural refrigerants, the industry would be able to reduce emission of CO2 and other greenhouse gases by 22 million metric tons annually. GreenChill is a partnership between the Environmental Protection Agency (EPA) and food retailers who use refrigerated equipment to reduce refrigerant emissions and thereby decrease the damage they can cause to the ozone layer. As part of this process, retailers are also encouraged to update their refrigerants during commercial refrigeration service to non-ozone depleting substitutes in their refrigerated equipment.

GreenChill is a partnership between the Environmental Protection Agency (EPA) and food retailers who use refrigerated equipment to reduce refrigerant emissions and thereby decrease the damage they can cause to the ozone layer. As part of this process, retailers are also encouraged to update their refrigerants during commercial refrigeration service to non-ozone depleting substitutes in their refrigerated equipment. The first approach to retrofitting retail refrigerated equipment during commercial refrigeration service involves replacing the refrigerant only. This approach is more cost effective and results in minimal changes to the refrigerated equipment. The second approach involves installing new mechanical systems during commercial refrigeration service which is obviously more costly. In addition to migrating to a non-ozone depleting refrigerant, the commercial refrigeration service could include installing new compressors, condensers, and cases.

The first approach to retrofitting retail refrigerated equipment during commercial refrigeration service involves replacing the refrigerant only. This approach is more cost effective and results in minimal changes to the refrigerated equipment. The second approach involves installing new mechanical systems during commercial refrigeration service which is obviously more costly. In addition to migrating to a non-ozone depleting refrigerant, the commercial refrigeration service could include installing new compressors, condensers, and cases.