In Commercial Refrigeration Equipment

Natural refrigerants are non-synthetic substances which can be used as cooling agents in commercial refrigeration equipment and air conditioners. These include naturally occurring substances like water, air, CO2, ammonia, and hydrocarbons like propane, butane, and cyclopentane. While they have been used for years as refrigerants they are only just now beginning to replace synthetic refrigerants in commercial refrigeration equipment.

Natural refrigerants are non-synthetic substances which can be used as cooling agents in commercial refrigeration equipment and air conditioners. These include naturally occurring substances like water, air, CO2, ammonia, and hydrocarbons like propane, butane, and cyclopentane. While they have been used for years as refrigerants they are only just now beginning to replace synthetic refrigerants in commercial refrigeration equipment.

Why Natural Refrigerants For Commercial Refrigeration Equipment?

While the Montreal Protocol addressed ozone depleting refrigerants like HCFCs and CFCs, it failed to address global warming potential of the proposed substitutes like HFCs. Increased scientific evidence has also shown that HFCs had huge potential to contribute to the greenhouse gas problem. So replacing HCFCs and CFCs with HFCs only displaced the problem. The only real solution to address both the ozone damaging and greenhouse gas problem created by refrigerants is to use natural refrigerants, including in commercial refrigeration equipment which is one of the largest consumers of refrigerant chemicals in the world.

The Economics Of Natural Refrigerants

Natural refrigerants are inexpensive to produce, in most cases even less expensive than HFCs; natural refrigerants are extremely energy efficient when used in large scale systems; and the disposal cost of natural refrigerants is negligible when compared to HFCs as well as older refrigerants like HCFCs. The major issue for commercial refrigeration equipment is the increase in capital expenditure required for small and medium businesses to convert to a natural refrigerant system. This is the major issue preventing wide spread adoption for natural refrigerants in commercial refrigeration equipment. Unlike retrofitting commercial refrigeration equipment with non-ozone depleting refrigerants, all natural refrigerant systems require a complete overhaul of the commercial refrigeration equipment.

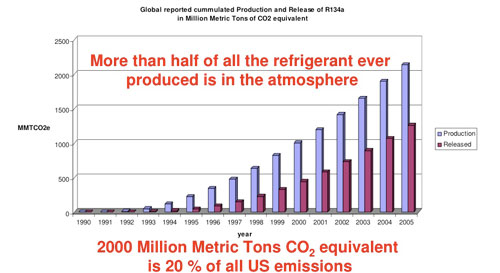

In spite of the economics of this issue, there is a worldwide push to switch to natural refrigerants in commercial refrigeration equipment. As of 2005, more than half of all synthetic refrigerants ever produced were in the atmosphere (AFEA S Alternative Fluorocarbons Acceptability Study, 2007). To reduce the Global Warming Potential and provide zero ozone depleting potential as required by the Montreal and Kyoto Protocols, commercial refrigeration equipment will eventually have to be cooled by natural refrigerants. It is estimated that if commercial refrigeration equipment in the United States alone was converted to natural refrigerants, the industry would be able to reduce emission of CO2 and other greenhouse gases by 22 million metric tons annually.

S Alternative Fluorocarbons Acceptability Study, 2007). To reduce the Global Warming Potential and provide zero ozone depleting potential as required by the Montreal and Kyoto Protocols, commercial refrigeration equipment will eventually have to be cooled by natural refrigerants. It is estimated that if commercial refrigeration equipment in the United States alone was converted to natural refrigerants, the industry would be able to reduce emission of CO2 and other greenhouse gases by 22 million metric tons annually.

GreenChill is a partnership between the Environmental Protection Agency (EPA) and food retailers who use refrigerated equipment to reduce refrigerant emissions and thereby decrease the damage they can cause to the ozone layer. As part of this process, retailers are also encouraged to update their refrigerants during commercial refrigeration service to non-ozone depleting substitutes in their refrigerated equipment.

GreenChill is a partnership between the Environmental Protection Agency (EPA) and food retailers who use refrigerated equipment to reduce refrigerant emissions and thereby decrease the damage they can cause to the ozone layer. As part of this process, retailers are also encouraged to update their refrigerants during commercial refrigeration service to non-ozone depleting substitutes in their refrigerated equipment. The first approach to retrofitting retail refrigerated equipment during commercial refrigeration service involves replacing the refrigerant only. This approach is more cost effective and results in minimal changes to the refrigerated equipment. The second approach involves installing new mechanical systems during commercial refrigeration service which is obviously more costly. In addition to migrating to a non-ozone depleting refrigerant, the commercial refrigeration service could include installing new compressors, condensers, and cases.

The first approach to retrofitting retail refrigerated equipment during commercial refrigeration service involves replacing the refrigerant only. This approach is more cost effective and results in minimal changes to the refrigerated equipment. The second approach involves installing new mechanical systems during commercial refrigeration service which is obviously more costly. In addition to migrating to a non-ozone depleting refrigerant, the commercial refrigeration service could include installing new compressors, condensers, and cases. Refrigeration equipment is a vital part of any food service establishment’s operations, so commercial refrigerator service should not be taken lightly. When looking for a technician to provide your commercial refrigerator service, you’ll want to find one that has certified training in the service of refrigeration equipment. The non-profit organization North American Technician Excellence, or NATE, specializes in certifying technicians in commercial refrigerator service and the field of refrigeration equipment.

Refrigeration equipment is a vital part of any food service establishment’s operations, so commercial refrigerator service should not be taken lightly. When looking for a technician to provide your commercial refrigerator service, you’ll want to find one that has certified training in the service of refrigeration equipment. The non-profit organization North American Technician Excellence, or NATE, specializes in certifying technicians in commercial refrigerator service and the field of refrigeration equipment. refrigerator service technician remain up to date. To accomplish this, NATE requires re-certification testing to keep technicians on the cutting edge of the refrigeration equipment industry.

refrigerator service technician remain up to date. To accomplish this, NATE requires re-certification testing to keep technicians on the cutting edge of the refrigeration equipment industry.