Here are a few things you can do to help keep the food and ingredients in your walk-in fresh and reduce waste for your business.

DON’T OVER STUFF YOUR WALK-IN REFRIGERATOR.

Make sure there is sufficient air circulation in your walk-in cooler. Cold air circulation prevents mold and other bacteria from having a chance to grow and flourish. There should be three inches of space between each container so all sides have access to fresh and flowing air. In addition to lack of circulation, over stuffing your unit leads to high utility bills since your walk-in usually has to work harder to cool more items.

BE STRATEGIC ABOUT ORGANIZATION.

More temperature sensitive foods such as raw meat and fish should be placed in the coldest areas of your unit. Generally, lower bottom shelves at back of your walk-in cooler tend to be coolest. Keep more stable items in warmer areas such as near the door (where warm air can infiltrate the cooler) and on top shelves (since heat rises).

MAKE SURE THE TEMPERATURE IS SET PROPERLY.

Depending on the inventory in your walk in cooler, items require different temperatures to stay fresh. Find out the best storage temperatures for your specific inventory and ensure that the unit is set to the correct temperature range.

LEAVE EXTRA ROOM ON THE FLOOR AND DIRECTLY BELOW THE CEILING FOR AIR MOVEMENT.

Bottom shelves should be six inches off the floor to allow for proper circulation as well

as easy cleaning. In addition, avoid stacking items all the way to the ceiling or it will

block air movement.

FOLLOW FIFO GUIDELINES AND LABEL FOOD WITH DATES.

FIFO means first in, first out. Whatever item has been in the unit the longest should be removed first. In addition, labeling is essential to an organized cooler and greatly assists in reducing food waste. Labels should include the contents of items as well as the date they entered the freezer and/or a produced on date.

Hopefully these tips will help you and your business reduce food waste and profit loss. Regular maintenance on your walk-in also ensures that it is working properly and storing your inventory to the best of its ability. Please contact us with any questions about food storage in your walk-in cooler

When you have a commercial refrigeration unit installed, you typically focus on things like the interior capacity, overall size to ensure it fits in your store, restaurant, or supermarket, as well as the efficiency of the unit and how much it costs to operate. However, one thing that you really need to consider is how to keep your unit safely operating.

When you have a commercial refrigeration unit installed, you typically focus on things like the interior capacity, overall size to ensure it fits in your store, restaurant, or supermarket, as well as the efficiency of the unit and how much it costs to operate. However, one thing that you really need to consider is how to keep your unit safely operating. old commercial refrigeration equipment, inefficient HVAC equipment, leaks in the system, over-sized compressors, out of date refrigerants, and commercial refrigeration units that were not designed correctly from the start. All of these issues can have drastic impact on a company’s bottom line due to the ever increasing cost of energy.

old commercial refrigeration equipment, inefficient HVAC equipment, leaks in the system, over-sized compressors, out of date refrigerants, and commercial refrigeration units that were not designed correctly from the start. All of these issues can have drastic impact on a company’s bottom line due to the ever increasing cost of energy. Natural refrigerants are non-synthetic substances which can be used as cooling agents in commercial refrigeration equipment and air conditioners. These include naturally occurring substances like water, air, CO2, ammonia, and hydrocarbons like propane, butane, and cyclopentane. While they have been used for years as refrigerants they are only just now beginning to replace synthetic refrigerants in commercial refrigeration equipment.

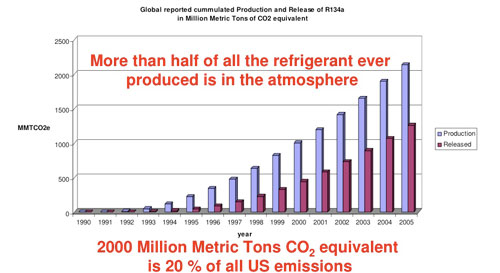

Natural refrigerants are non-synthetic substances which can be used as cooling agents in commercial refrigeration equipment and air conditioners. These include naturally occurring substances like water, air, CO2, ammonia, and hydrocarbons like propane, butane, and cyclopentane. While they have been used for years as refrigerants they are only just now beginning to replace synthetic refrigerants in commercial refrigeration equipment. S Alternative Fluorocarbons Acceptability Study, 2007). To reduce the Global Warming Potential and provide zero ozone depleting potential as required by the Montreal and Kyoto Protocols, commercial refrigeration equipment will eventually have to be cooled by natural refrigerants. It is estimated that if commercial refrigeration equipment in the United States alone was converted to natural refrigerants, the industry would be able to reduce emission of CO2 and other greenhouse gases by 22 million metric tons annually.

S Alternative Fluorocarbons Acceptability Study, 2007). To reduce the Global Warming Potential and provide zero ozone depleting potential as required by the Montreal and Kyoto Protocols, commercial refrigeration equipment will eventually have to be cooled by natural refrigerants. It is estimated that if commercial refrigeration equipment in the United States alone was converted to natural refrigerants, the industry would be able to reduce emission of CO2 and other greenhouse gases by 22 million metric tons annually.