In Commercial Refrigeration and HVAC

It has been stated that 30% of the energy used to heat or cool a building or a commercial refrigeration unit is wasted. This is caused by old commercial refrigeration equipment, inefficient HVAC equipment, leaks in the system, over-sized compressors, out of date refrigerants, and commercial refrigeration units that were not designed correctly from the start. All of these issues can have drastic impact on a company’s bottom line due to the ever increasing cost of energy.

old commercial refrigeration equipment, inefficient HVAC equipment, leaks in the system, over-sized compressors, out of date refrigerants, and commercial refrigeration units that were not designed correctly from the start. All of these issues can have drastic impact on a company’s bottom line due to the ever increasing cost of energy.

How Does Energy Optimization Work?

There are many ways to improve the efficiency of a commercial refrigeration or HVAC system. Some of them are expensive and some of them are not. The first step in improving the efficiency of your system and thereby reducing your energy costs would be an Energy Optimization Audit.

A technician certified in energy optimization can provide you with an audit that will clearly specify how to improve your heating and cooling efficiency. Ways to improve your energy optimization could include the following:

- Refrigerant Retrofits

- Eliminating Leaks In Your HVAC, Ventilation & Commercial Refrigeration Systems

- Installing Energy Efficient Lighting In Your Commercial Refrigeration Equipment

- Installing Modern Control Units

- Installing Variable Speed Motors On Heating and Cooling Equipment

- Upgrading To More Efficient Compressors For Your Commercial Refrigeration & HVAC Equipment

- Scheduling Regular Maintenance On Existing Refrigeration & HVAC Equipment

The recommendations from your Energy Optimization Audit can be simple and inexpensive ways to lower your energy costs or they could be more expensive. Simple, inexpensive ways to improve the efficiency of your commercial refrigeration or HVAC system could include regularly scheduled maintenance and eliminating leaks. More expensive recommendations to improve your energy efficiency could include replacing the compressors in your refrigeration equipment or HVAC system or possibly complete system upgrades.

The Results Of An Energy Optimization Audit

The bottom line is that energy savings means better business. If you’re wasting energy, and therefore money, needlessly it will continue to be a drag on your company’s profitability. An efficient business is a successful business. An Energy Optimization Audit will give you the tools, resources, and possibly even rebates necessary to improve the energy efficiency of your business.

Natural refrigerants are non-synthetic substances which can be used as cooling agents in commercial refrigeration equipment and air conditioners. These include naturally occurring substances like water, air, CO2, ammonia, and hydrocarbons like propane, butane, and cyclopentane. While they have been used for years as refrigerants they are only just now beginning to replace synthetic refrigerants in commercial refrigeration equipment.

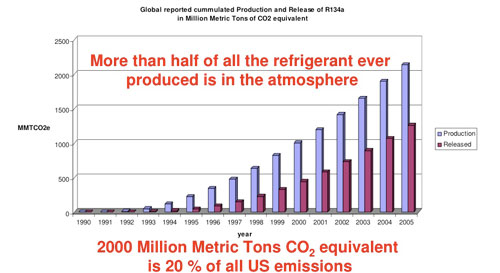

Natural refrigerants are non-synthetic substances which can be used as cooling agents in commercial refrigeration equipment and air conditioners. These include naturally occurring substances like water, air, CO2, ammonia, and hydrocarbons like propane, butane, and cyclopentane. While they have been used for years as refrigerants they are only just now beginning to replace synthetic refrigerants in commercial refrigeration equipment. S Alternative Fluorocarbons Acceptability Study, 2007). To reduce the Global Warming Potential and provide zero ozone depleting potential as required by the Montreal and Kyoto Protocols, commercial refrigeration equipment will eventually have to be cooled by natural refrigerants. It is estimated that if commercial refrigeration equipment in the United States alone was converted to natural refrigerants, the industry would be able to reduce emission of CO2 and other greenhouse gases by 22 million metric tons annually.

S Alternative Fluorocarbons Acceptability Study, 2007). To reduce the Global Warming Potential and provide zero ozone depleting potential as required by the Montreal and Kyoto Protocols, commercial refrigeration equipment will eventually have to be cooled by natural refrigerants. It is estimated that if commercial refrigeration equipment in the United States alone was converted to natural refrigerants, the industry would be able to reduce emission of CO2 and other greenhouse gases by 22 million metric tons annually. GreenChill is a partnership between the Environmental Protection Agency (EPA) and food retailers who use refrigerated equipment to reduce refrigerant emissions and thereby decrease the damage they can cause to the ozone layer. As part of this process, retailers are also encouraged to update their refrigerants during commercial refrigeration service to non-ozone depleting substitutes in their refrigerated equipment.

GreenChill is a partnership between the Environmental Protection Agency (EPA) and food retailers who use refrigerated equipment to reduce refrigerant emissions and thereby decrease the damage they can cause to the ozone layer. As part of this process, retailers are also encouraged to update their refrigerants during commercial refrigeration service to non-ozone depleting substitutes in their refrigerated equipment. The first approach to retrofitting retail refrigerated equipment during commercial refrigeration service involves replacing the refrigerant only. This approach is more cost effective and results in minimal changes to the refrigerated equipment. The second approach involves installing new mechanical systems during commercial refrigeration service which is obviously more costly. In addition to migrating to a non-ozone depleting refrigerant, the commercial refrigeration service could include installing new compressors, condensers, and cases.

The first approach to retrofitting retail refrigerated equipment during commercial refrigeration service involves replacing the refrigerant only. This approach is more cost effective and results in minimal changes to the refrigerated equipment. The second approach involves installing new mechanical systems during commercial refrigeration service which is obviously more costly. In addition to migrating to a non-ozone depleting refrigerant, the commercial refrigeration service could include installing new compressors, condensers, and cases. As food service equipment goes, the walk in cooler is probably one of the most important pieces of refrigeration equipment a restaurant owner will invest in. As previously discussed, the right walk in cooler can drastically impact a restaurant’s bottom line. If the walk in cooler is too big, then the restaurant is keeping too much air cold. If this vital piece of refrigeration equipment is too small, then profits will be eroded by spoiled perishable items, and the restaurant owner’s food service equipment could be putting them out of business. So the walk in cooler is a very important piece of food service equipment.

As food service equipment goes, the walk in cooler is probably one of the most important pieces of refrigeration equipment a restaurant owner will invest in. As previously discussed, the right walk in cooler can drastically impact a restaurant’s bottom line. If the walk in cooler is too big, then the restaurant is keeping too much air cold. If this vital piece of refrigeration equipment is too small, then profits will be eroded by spoiled perishable items, and the restaurant owner’s food service equipment could be putting them out of business. So the walk in cooler is a very important piece of food service equipment. Keeping the air flowing smoothly and keeping condenser coils cleaned is vital to proper operation of any piece of refrigeration equipment. This means proper ventilation, regularly cleaning filters, and regular check-ups with a certified technician. From time to time the refrigerant will need to be replaced, and per state regulations this can only be done by a refrigeration equipment technician who is certified. When regular maintenance of your walk in cooler is not performed your are increasing the odds of it breaking down prematurely. Almost always, your walk in cooler will break down on the hottest day of the year when your establishment is busy and you need your food service equipment the most. To add insult to injury it will probably happen on a Saturday night when all of the refrigeration equipment technicians are unavailable.

Keeping the air flowing smoothly and keeping condenser coils cleaned is vital to proper operation of any piece of refrigeration equipment. This means proper ventilation, regularly cleaning filters, and regular check-ups with a certified technician. From time to time the refrigerant will need to be replaced, and per state regulations this can only be done by a refrigeration equipment technician who is certified. When regular maintenance of your walk in cooler is not performed your are increasing the odds of it breaking down prematurely. Almost always, your walk in cooler will break down on the hottest day of the year when your establishment is busy and you need your food service equipment the most. To add insult to injury it will probably happen on a Saturday night when all of the refrigeration equipment technicians are unavailable.